Integrated Solution For Short Process Steelmaking

Integrated Solution For Short Process Steelmaking

More

Company News

Joint Research Institutions

Integrated Solution For Short Process Steelmaking

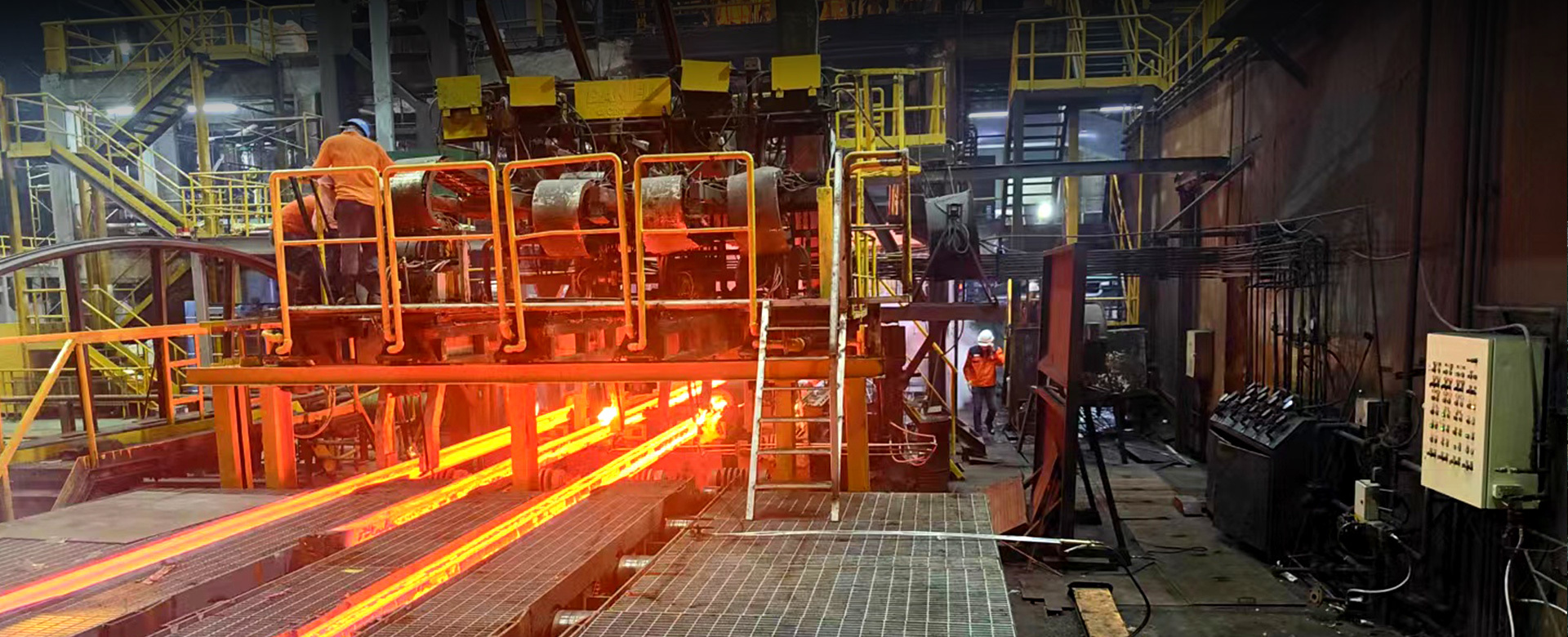

The short process steel enterprise solution mainly focuses on the electric furnace steelmaking process with scrap as the main raw material, which has the advantages of energy saving, carbon reduction, production flexibility, etc. The short process steel enterprise solution realizes green and flexible production by optimizing the process technology, raw material supply, energy management and production management, etc., which has significant energy saving and carbon reduction effects and market competitiveness...

Steelmaking Producing Contacting Service Mode

Our steel production contracting program, comprehensive integration of resources, with rich industry experience and management mode, through the optimization of production processes, manpower and equipment, not only can significantly increase the production capacity of the steel plant, reduce production costs, but also ensure product quality and stability to meet industry standards, to help steel mills to achieve the economic benefits and market competitiveness of the double leap...