Operating conditions of refractory materials in oxygen converters

2025-03-19

(1) Overview of Refractory Materials Used in Various Countries

In some countries, oxygen converters have replaced open-hearth furnaces. China also completed this replacement in 1998. In oxygen converters, refractory materials are subjected to alkaline slag, oxidizing and reducing gases, metals at temperatures around 1700℃, and intense mechanical abrasion due to the turbulent circulation of metal and slag. Oxygen converters generally use CaO-MgO-C refractory materials, with magnesia-carbon bricks being most prevalent. Practices vary among countries; Japan tends to use magnesia-carbon bricks of different grades exclusively. However, European countries use a combination of pitch-bonded magnesia-carbon bricks and carbon-containing dolomite (or magnesia-dolomite) bricks for the furnace lining. While their service life is not as long as that of the all-magnesia-carbon brick linings in Japan, they are more cost-effective.

In tar-bonded magnesia-dolomite products, the MgO/CaO ratio has been continuously increasing with the intensification of converter production. Dolomite products contain free lime; although tar binder prevents lime hydration, cracking occurs in the large-grained dolomite during the molding process, creating fresh surfaces without tar protection. With higher CaO content in the product, hydration stability decreases. Although the materials of furnace linings vary among countries, there is a consensus on the need for high-purity raw materials, whether sintered or electrofused, i.e., the use of refined materials.

(2) Service Conditions of Different Parts of the Furnace Lining

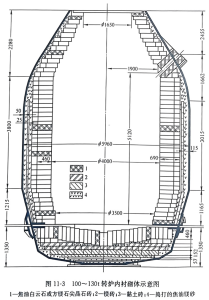

Due to differences in operating conditions and operational factors in various parts of the converter lining, the erosion rate is extremely uneven. The trunnions, slag line, roof, and tapping hole are prone to premature failure, rendering the entire lining unusable even if other parts remain intact. Therefore, converter linings typically utilize 5-7 different types of refractory materials, each for different parts of the lining; tar-bonded dolomite or magnesia-dolomite products form the main body of the lining. Additionally, fired magnesia products, either tar-impregnated or not, are used. Figure 11-3 shows the lining structure of a 100-130t converter in a certain country. High-purity magnesia or high-purity magnesia-dolomite products, even those that are inherently strong and slag-resistant fired refractories, are ineffective as converter linings without carbon. This is because the working layer is quickly permeated by slag and spalls under thermal stress. The carbon near the working surface turns into fine-grained graphite, which is not wetted by the slag, limiting the depth of slag penetration into the refractory material.

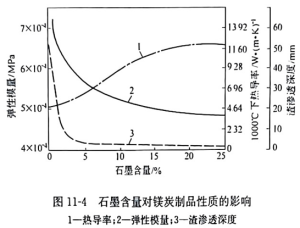

Therefore, efforts are made to increase the carbon content in converter refractory materials. A simple method is to add carbon to oxide refractory materials. When producing unfired magnesia-carbon products, graphite is added to the mix, along with a tar-pitch binder, resulting in a carbon content of 23% in the product. The wear rate of this type of product is lower, at 0.66 mm/heat. However, at the high temperatures during tapping, due to the reduction reaction of carbon-enhanced periclase to a gaseous state, a significant reduction in product service life has been observed. The effect of graphite content on slag penetration depth and other properties of magnesia-carbon refractory materials is shown in Figure 11-4. The graph shows that when the carbon content is 5%, slag penetration is significantly reduced. With higher carbon content, the service life of magnesia-carbon refractory linings is fundamentally improved. Therefore, carbon not only impedes slag penetration but also inhibits the slagging process of the refractory material itself.