Application of High-Efficiency Continuous Casting Tundish Refractory Materials (Part 2)

2025-07-23

Application of negative pressure baking and flow guide rod in the middle of the slide block

2.1 Current Status of the Inlet

The tundish nozzle material is made of zirconia refractory material or a composite material of high-alumina material with zirconia inner lining (1-3). It must be fully baked before casting; otherwise, there is a risk of flow and cracking during casting. Currently, the baking of the tundish nozzle mainly relies on the coal gas flame during the baking process of the tundish refractory material, but due to the limitation of heat overflow and the coal gas flame cannot penetrate the nozzle, only a small part is fully baked, and the baking effect is not ideal. Flow, nozzle cracking and subsequent nozzle steel leakage and leakage accidents occur from time to time, and the service life of the continuous casting tundish is difficult to improve. After the existing tundish is turned over, the steel column is nodular, the service life is short, and the expansion is obvious. Before baking, add flow sand, because the inlet cannot be baked in place, the flow sand completely covers the inlet, and the tundish baking is difficult to penetrate the lower slide block, resulting in poor baking effect of the inlet, and problems such as nozzle dropping and cracking.

on site situation of tundish inner lining with steel reinforcement

2.2 Application of Negative Pressure Baking

The negative pressure baking device for the tundish nozzle is shown in Figure 3. During the baking process of the tundish refractory material, the baking of the nozzle can be achieved simultaneously, without the need to install a separate coal gas baking device. The baking intensity is easy to adjust, the heating is uniform, and the baking effect is good; the center temperature before casting can reach 850℃, which greatly reduces the frequency of tundish flow and the risk of nozzle cracking, meets the production needs of steelmaking, solves the problems of nozzle dropping and cracking, and improves the baking effect of the inlet

Picture 3 Application of negative pressure baking for tundish sizing nozzle

2.3 Application of Flow Guide Rod

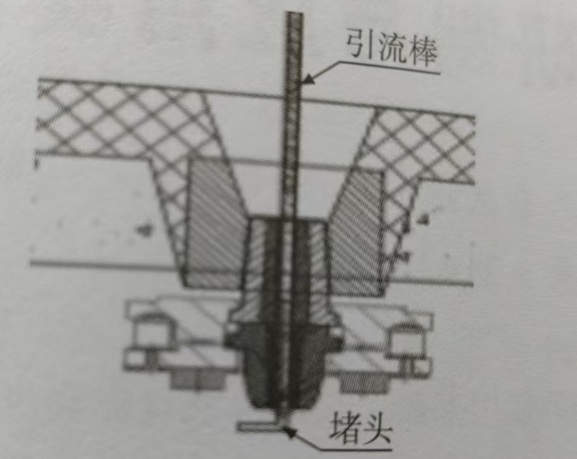

In order to solve the problem of flow at the beginning of casting, a flow guide rod is used. The flow guide rod is made with a paper shell, and both ends are plugged with paper balls. The specifications are 1000mm long,

outer diameter 15.7 mm, wall thickness 1.5 mm, and the inside is filled with 400mm flow sand (chromium oxide content greater than 32%) and 600mm ferrosilicon alloy (alloy particle size 3~6mm,

silicon content 75%~80%). Before installing and baking the tundish, clean the impurities in the inlet and seat bricks.

Turn off the tundish baking device before casting,

remove the negative pressure device, and purge the tundish inlet again to remove internal impurities. Insert the flow guide rod into the lower slide block and the inlet, and use the plug to plug the lower slide block zirconia core,

As shown in Figure 4. After the outer paper shell of the flow guide burns in the tundish, the ferrosilicon and flow sand are scattered in the nozzle, playing a role in guiding the flow. After the casting operation, remove the plug inside the lower slide block,

Picture 4 Schematic diagram of diversion rod usage

Previous Page: