Application of High-Efficiency Continuous Casting Tundish Refractory Materials (Part 1)

2025-07-22

Optimization of tundish lining construction method

1.1 Pre-embedded impact plate in the permanent layer of the bottom impact zone

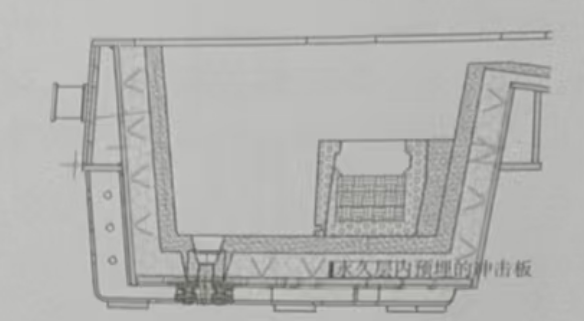

The impact zone of the tundish is the most severely eroded part, especially the bottom impact zone, which needs to withstand the continuous mechanical impact of the steel flow, thus becoming the weakest part of the tundish. Although the original design installed special flow stabilizers to enhance the safety factor of the impact zone, there is still a possibility of the flow stabilizer and the working layer being pierced. Therefore, the construction method adopts the method of pre-embedding an impact plate in the permanent layer to enhance the safety factor of the impact zone, as shown in Figure 1.

Schematic diagram of tundish permanent lining for pre-embedded impact plate

1.2 Sharp angle transition between the impact zone side and the small side of the tundish

Currently, the transition between the side of the tundish impact zone and the small side is subject to severe scouring and erosion. According to on-site tracking statistics, the erosion rate of the working layer in this area is 1.7 times faster than other parts of the tundish. For this reason, the side of the impact zone and the small side are designed with a sharp angle transition, and the thickest part of the working layer can reach 180mm (other parts of the working layer are 100mm), achieving synchronous erosion of the tundish working layer and improving the safe use of the tundish.

1.3 Improve the bonding strength between the permanent layer and the working layer

The working layer of the tundish mainly uses electrofused magnesia or sintered magnesia as the main raw material, supplemented by various binders to form a magnesia dry material. The permanent layer generally uses high-alumina castable (A10:>55%). The bonding methods of the two materials are different. The length of the large side of our company's tundish reaches more than 9500mm, while the thickness of the working layer is only 100mm. The bonding strength between the permanent layer and the working layer is low, and collapse accidents are prone to occur during the construction and baking process. The surface of the tundish permanent layer is treated, and steel bars are welded as shown in Figure 2. After the permanent layer is peeled off, shallow grooves appear on its surface, increasing the contact area with the working layer and improving the bonding strength. In addition, optimizing the composition of the dry material, standardizing the material distribution and vibration baking, and increasing the thickness of the release agent can improve the success rate of demolding.

Previous Page: