Extend the lifespan of blast furnace slag skimmers

2025-07-21

In the maintenance technology and application process of blast furnace iron produce, the skimmer is an essential key component. Usually, after the smelting of molten iron in blast furnaces, it needs to flow through the main channel to the slag skimmer for slag iron separation. That is to say, the slag skimmer is a slag iron separation equipment designed for the continuous tapping requirements of blast furnaces. Therefore, the service life of the slag skimmer is crucial for the overall service life of the blast furnace iron groove, and it is necessary to improve its service life and operational efficiency through structural optimization and material upgrading.

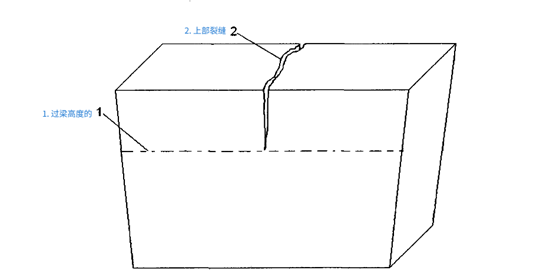

At present, most skimmers adopt prefabricated modular design, and the use of ASC material system has become a consensus. However, there are still many improvements in the structured design of skimmers. Prefabricated skimmer beams are particularly prone to longitudinal cracking in the middle during use, leading to slag leakage and passing problems. The main reason for cracking is that the lower part of the lintel is immersed in high-temperature molten iron at a temperature of around 1450 ℃, causing significant thermal expansion of the refractory material. The upper part, which has a height of about 1/3 to 1/5, is exposed to air at a lower temperature, with a surface temperature generally only around 300 ℃. Its linear expansion is obviously much smaller than that of the lower part of the lintel. Therefore, cracking usually starts from the upper part and usually occurs 2-3 furnaces after iron removal, gradually expanding and extending downwards as shown in the following figure:

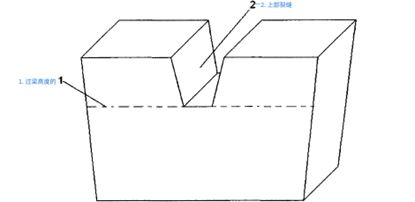

Design a gap structure in the middle of the upper part of the prefabricated beam, and fill this gap with castables or refractory materials such as mortar after baking the prefabricated components. The lowest position of the lower edge of the gap is designed to be close to the liquid level line in the main iron groove. The gap can be designed as an inverted trapezoid, or as a rectangle or U-shape, as shown in the following figure:

When the beam expands due to heat, the part below the liquid level will become laterally elongated. If there is no gap reserved in the middle above the liquid level line, the upper part will inevitably be pulled apart and cracked. Now there is a gap reserved in the upper part, so there will be no gap in the middle of the prefabricated part above the line, so there will be no more cracks in the upper part, and of course, there is no possibility of cracks extending downwards. After the beam is put into use, fill the gap with pouring material or ramming material. This structure of the skimmer avoids the occurrence of cracks and greatly extends its service life.

Previous Page: