Application of magnesia-carbon bricks in LF-VD furnace slag lines

2025-07-31

With the development of metallurgical technology worldwide, short-process production lines and ladle refining have rapidly advanced in recent years. Therefore, IF furnaces and IF-VD furnaces have developed very quickly. They are not only essential for short-process production lines but are also used in long-process production lines.

Magnesia-carbon bricks for slag lines are made using high-quality magnesia, high-purity graphite, and additives such as metallic silicon and silicon carbide, with phenolic resin as a binder. Used in LF refining furnaces, in the slag line area of the refining furnace, they can improve the service life of the ladle.

The Influence of Fine Magnesia Powder Content on the Properties of Magnesia-Carbon Bricks

Reducing the fine particle content in magnesia-carbon bricks is beneficial for increasing the density of the bricks. Increased density should improve their oxidation and erosion resistance.

The Influence of Magnesia Particle Composition on the Properties of Magnesia-Carbon Bricks

The internal oxidation-reduction gasification reactions in ultra-high-temperature magnesia-carbon materials are very significant. The greater the reaction amount, the greater the sample shrinkage, and the lower the strength. Therefore, when using magnesia-carbon materials at ultra-high temperatures or under vacuum, the oxidation-reduction reaction between MgO and C should be considered, and an appropriately small amount of fine magnesia particles should be selected to reduce the contact area between magnesia and carbon, thereby reducing the reaction amount.

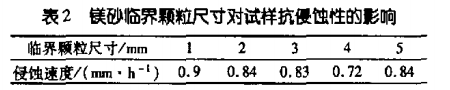

The Influence of Critical Magnesia Particle Size on Erosion Resistance

When the mass fraction of graphite is 10%, the influence of the critical particle size of magnesia on the erosion resistance of magnesia-carbon samples was investigated. The erosion test was conducted in an induction furnace. A 25mm x 25mm x 125mm sample was attached to the induction furnace lining, steel and LF slag were added, and the erosion test was conducted at 1600℃ for 3 hours. Then, the erosion amount was measured, and the erosion rate was calculated. The results are shown in Table 2.

The critical particle size of magnesia-carbon samples may vary depending on the tonnage of the furnace. This experimental method should be used to obtain the value of the critical magnesia particle size.

The Influence of CaZrO₂ Addition Amount on Erosion Resistance

Under the conditions of a graphite mass fraction of 10% and a BC mass fraction of 1.5%, a 25mm x 20mm x 125mm sample was prepared using calcium zirconate instead of magnesia, and an induction furnace erosion test was conducted. The sample was attached to the furnace lining. Test conditions: 10kg of steel was added, and 1648g of IF slag was added in three portions. The test temperature was approximately 1600℃, and the holding time was 1 hour. When the mass fractions of calcium zirconate were 0%, 10%, and 20%, the erosion rates were 1mm/h, 1.75mm/h, and 2.3mm/h, respectively. The test results show that as the amount of CaZrO₂ added increases, the erosion rate increases, but the slag adhesion is significantly improved. Microscopic analysis of the eroded samples shows that the reason for the faster erosion with the addition of calcium zirconate is that at high temperatures, calcium zirconate reacts with the slag and additives such as aluminum and silicon in the magnesia-carbon brick, resulting in significant volume expansion, which destroys the structure and strength of the brick!

1.5 The Influence of Additives on Erosion Resistance

With a graphite mass fraction of 10%, magnesia-carbon samples were prepared using different additives, and slag erosion tests were conducted on an induction furnace. Test conditions: 10kg of steel, IF slag and slag removal were added 6 times, a total of approximately 3008g of slag was added, the test temperature was 1600-1650℃, and the holding time was 115 minutes. The results show that without additives, the erosion index was 100. When special additives and aluminum powder were added, the erosion indices were 62 and 68, respectively. When silicon powder was added, the erosion index was 128. This shows that adding a small amount of special antioxidants can significantly improve the slag resistance of magnesia-carbon bricks. Aluminum powder also has good erosion resistance. Adding silicon powder makes the erosion resistance of magnesia-carbon bricks worse.

1.6 The Influence of Additives on the Oxidation Resistance of Magnesia-Carbon Bricks

Oxidation resistance tests were conducted on magnesia-carbon bricks with a graphite mass fraction of 10% using different additives: Samples were placed in a resistance furnace, air was passed into the furnace at a rate of 240 l/h, the temperature was raised to 900℃ within 2 hours, and held for 4.5 hours before the furnace was stopped. After stopping the furnace, air was continued to be passed through for 3 hours, at which time the furnace temperature dropped to 500℃, and the air supply was stopped, and the sample was allowed to cool naturally to room temperature. The sample was removed from the resistance furnace, cut in half, and the diameter of the carbon-containing layer and the diameter of the sample were measured to calculate the percentage of the oxidized area. When aluminum powder, special additives, aluminum-magnesium alloy powder, and boron carbide-silicon powder composite powder were added, the percentage of the oxidized area was 28.7%, 1.12%, 18.8%, and 3.2%, respectively. The results show that the oxidation resistance of magnesia-carbon brick samples containing special additives is significantly better than that of samples containing metallic aluminum powder, aluminum-magnesium powder, and boron carbide-silicon powder composite powder. Therefore, adding special additives to magnesia-carbon bricks and other carbon-containing refractory materials will significantly reduce the thickness of the oxidation decarbonization layer.

Previous Page:

Next Page: