Application of High-Efficiency Continuous Casting Intermediate Vessel Refractory Materials (Part 4)

2025-07-25

4, Application of the double-joint upper water inlet during the double festival

4.1 Causes of expansion, cracking, and nodulation of the upper water inlet

There are two forms of erosion, expansion, and cracking of the intermediate tundish upper water inlet: one is the appearance of point-like steel nodules on the surface of the residual steel; the other is the appearance of longitudinal cracks in the zirconium core, with steel overflowing from the steel column and steel sheets being squeezed out. The expansion and cracking of the intermediate tundish upper water inlet zirconium core is related to the quality stability of the water inlet zirconium core. The main component of the upper water inlet zirconium core is ZrO2, with a small amount of MgO, yttrium oxide (Y2O3), and other rare earth stabilizers added. The binder is generally polyethylene alcohol zirconium oxide. When the temperature changes, phase structure transitions of monoclinic, tetragonal, and cubic crystal systems will occur, with volume changes during this process. Therefore, the thermal shock resistance of zirconia is very poor. In order to improve the thermal shock resistance of the zirconium core, a partially stabilized method is used to produce the zirconium core. The finished zirconium core is a partially stabilized zirconia material, with a stabilization rate of generally 30%. In the later stage of use in the intermediate tundish, the stabilization rate of the water inlet decreases, which is manifested as a decrease in the erosion resistance and thermal shock resistance of the water inlet zirconium core, causing erosion and cracking of the upper water inlet. The use of the traditional H160 upper water inlet presents significant safety risks. The faster the continuous casting speed, and the shorter the zirconium core channel of the upper water inlet, the more turbulent the steel flow field will be, directly scouring the zirconium core of the upper water inlet, resulting in faster water inlet expansion, and bringing greater risks to the safe production of continuous casting.

4.2 Design of the double-joint upper water inlet

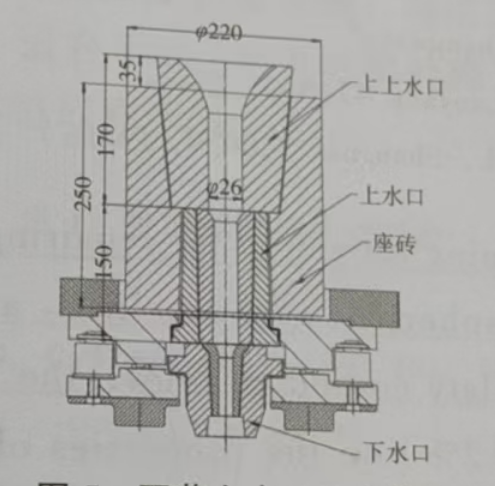

As shown in Figure 5, the double-joint upper water inlet consists of an upper water inlet and an upper-upper water inlet. This increases the height of the upper water inlet and improves its service life. The double-joint upper water inlet has a longer channel, and under high casting speeds, the steel flow field will be more stable than that of the H160. The steel will directly scour the upper-upper water inlet, flowing into the upper water inlet through the upper-upper water inlet, reducing the degree of scouring of the water inlet, and significantly alleviating the expansion of the water inlet, greatly improving the service life of the water inlet. The design uses a double-joint upper water inlet to increase the height of the upper water inlet, optimize the water inlet flow field, reduce the erosion of the steel on the water inlet zirconium core, and solve the problems of steel penetration between the water inlet matrix and the zirconium core, and erosion and expansion of the upper part of the zirconium core.

4.3 Adjustment of zirconium core composition

In response to the expansion and cracking of the water inlet, the material of the water inlet zirconium core is optimized. High-quality ZrO2 is selected, and the ZrO2 content of the zirconium core is increased to over 95%, improving physical properties such as bulk density and apparent porosity. At the same time, the amount of MgO and Y2O3 composite stabilizer is adjusted, increasing from 2.95% to 2.99%, optimizing the stabilization rate of the zirconium core, and improving the erosion resistance of the water inlet. The physical and chemical properties before and after the adjustment are listed in Table 2.

Schematic Diagram of Double-Joint Upper Water Inlet

Table 2 Comparison of Physical and Chemical Properties of Zirconium Core Before and After Adjustment

| Item | Apparent porosity (%) | Bulk density (g/cm³) | High-temperature compressive strength/Mpa | ZrO₂% |

| Zirconium core before improvement | ≤12 | 90 | 90 | 93 |

| Zirconium core after improvement | ≤10 | 100 | 100 | 95 |

Previous Page:

Real-time Information

■

—

2025-07-25