Development Prospect of Refractory Materials under the Dual Carbon Policy

2025-07-17

China has clearly proposed the "dual carbon goals" of striving to achieve carbon peaking before 2030 and carbon neutrality before 2060. Therefore, the next 40 years will be a period of extensive and profound economic and social transformation. The refractory materials industry is a high energy-consuming and polluting industry. The dual carbon conditions pose many challenges to the development of refractory materials. It can be said that the refractory materials industry has a long way to go to achieve the dual carbon goals. Refractory material manufacturers need to vigorously develop monolithic refractory materials to seek opportunities under the dual carbon background. The reasons are as follows:

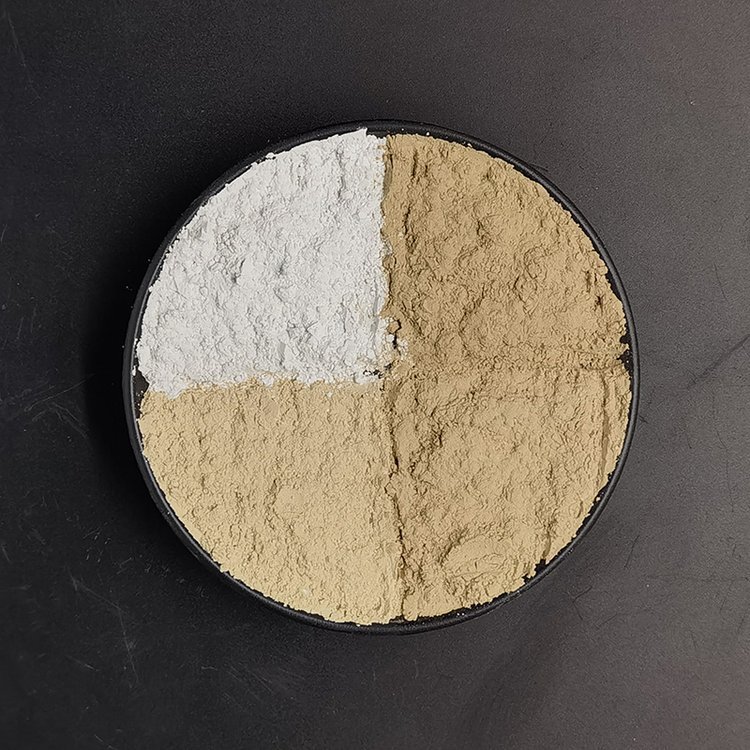

(1) Monolithic refractory materials are composed of aggregates, powders, binders, and additives. They do not require molding and firing; they can be used simply by adding appropriate liquid for mixing. The production process is relatively simple, the production cycle is short, and the comprehensive energy consumption is low, only 1/8 of that of fired products. It is a fully enclosed automated production line that can be controlled by computer, with no dust leakage and no environmental pollution.

(2) Monolithic refractory materials are flexible to use and have high mechanization efficiency. They can be cast and patched on the residual body, and can also be used for local repairs. They are especially suitable for the construction and repair of complex linings and are easy to adjust their composition and properties.

(3) Monolithic refractory materials do not require firing, and prefabricated parts are heat-treated at lower temperatures, which conforms to the concept of green refractory materials and is a representative achievement in the green development of refractory materials.

In recent years, monolithic refractory materials have developed rapidly in some developed countries. Currently, in the total global output of refractory materials, Japan's output of monolithic refractory materials accounts for more than 65%, and that of European and American countries is also more than 50%, while China's is around 36%, indicating significant room for development.

For places where shaped refractory products must be used, unfired products, i.e., unfired bricks, should be used as much as possible. This brick belongs to monolithic refractory materials because it uses the production technology of monolithic refractory materials, only with an additional molding process. Therefore, the production prospect of monolithic refractory materials is broad under the dual carbon background.

Previous Page:

Real-time Information

■

—

2025-07-25