Refractory castable for electric furnace lid

2025-08-13

Electric arc furnaces are industrial furnaces that primarily use recycled steel as raw material. They use electricity as a heat source, employing high temperatures generated by electric arcs between electrodes and the furnace charge to melt the material. The furnace environment is harsh, and the process ultimately yields finished steel products. The furnace lining mainly consists of basic refractory materials; magnesia refractory materials are used for lining, significantly removing harmful elements such as phosphorus, sulfur, and other impurities from the steel. Electric furnace roofs typically use high-alumina refractory materials. Previously, furnace roofs were mostly built with refractory bricks; now, high-alumina castables are used for on-site casting or prefabrication. Depending on the size of the furnace roof, they are processed and manufactured to meet the requirements of the electric furnace roof.

Electric furnace roof castables use high-grade natural bauxite as the primary refractory raw material, with the addition of clay clinker, aluminate cement, and other additives, mixed according to a formulated ratio, and blended to form the castable. During construction, the addition of appropriate amounts of water allows for casting.

High-alumina castables, used as electric furnace roof castables, exhibit good thermal shock resistance, high wear and corrosion resistance, high-temperature compressive strength, good spalling resistance, and slag resistance, making them suitable for the working environment of electric furnace roofs.

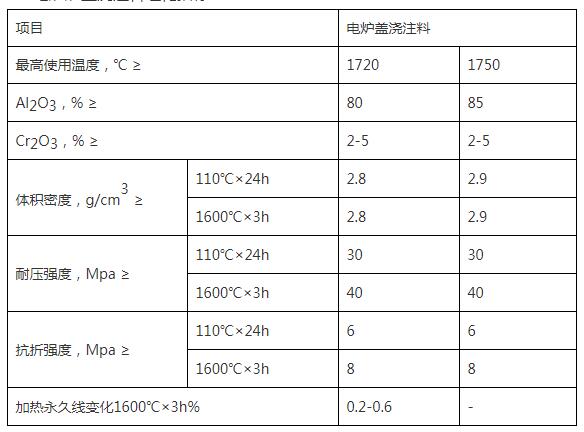

Physicochemical Indicators of Electric Furnace Roof Castables

Whether prefabricated or cast on-site, high-alumina castables can be used for electric furnace roofs. They can be used to produce ultra-high power electric furnace roofs and refining furnace roofs, regardless of whether they are circular or triangular; construction can be adapted to the size and thickness of the electric furnace roof. If the furnace roof is prefabricated off-site, it can be transported to the steel plant for direct use.

Electric furnace roofs cast using high-alumina castables offer good integrity and ease of construction, superior to refractory brick construction, making them the current preferred refractory material for electric furnace roofs.

Previous Page: