Production and use of magnesia-carbon monolithic steel tapping nozzles

2025-08-04

Production of magnesia-carbon steel nozzle bricks

Raw materials used include electrofused magnesia, electrofused magnesia (MgO>90%)-194 mesh flake graphite, phenolic resin, additives such as SiC silicon powder, high-temperature asphalt, etc.

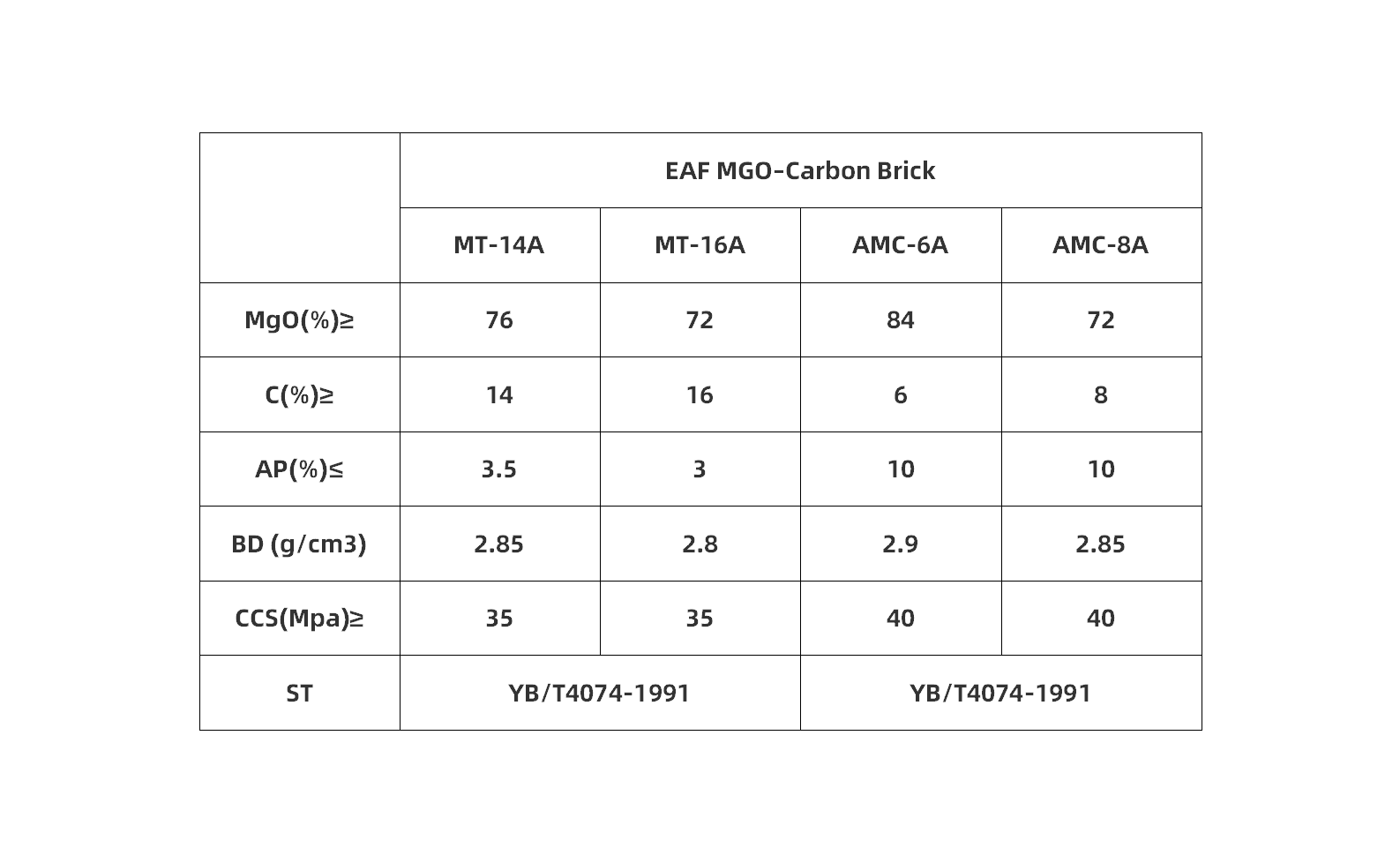

The physicochemical indicators of magnesia-carbon steel nozzle bricks are as follows

From the table above, it can be seen that adding an appropriate amount of high-temperature asphalt powder significantly reduces the apparent porosity of the overall steel nozzle brick, the bulk density does not change significantly, and when the critical particle size of the magnesia aggregate decreases, the apparent porosity decreases, and the bulk density also decreases.

Application of magnesia-carbon monolithic steel nozzle bricks

The erosion of magnesia-carbon steel nozzle bricks is considered to be caused by gas-phase oxidation-structural degradation-abrasive erosion. A refractory materials factory uses an isostatic press to produce magnesia-carbon steel nozzle bricks, which are used in the converter workshop of a steel company. The steel grades are boiling steel, calm steel, and 20MnSi, and the tapping temperature is 1750~1760℃. The service life has increased from the original several times of the sleeve brick to more than fifty times, and the erosion rate is about 1/3~1/4 of the original. It is evident that the service life of the isostatically pressed monolithic steel nozzle brick is significantly better than that of the combined steel nozzle brick.

Magnesia-carbon monolithic steel nozzle bricks have a safe and reliable structure, a long service life, reduce the number of steel nozzle replacements, improve the operating rate and stability of converter operation, and increase steel production.

Conclusion

The magnesia-carbon monolithic steel nozzle bricks produced by a 600MPa isostatic press are innovative. They have superior performance compared to magnesia-carbon combined steel nozzles. The monolithic steel nozzle bricks have a reasonable critical particle size, uniform and dense materials inside the brick, low porosity, and structural stability, with good hot strength and oxidation resistance. After use in the converter workshop, the effect is better than that of the combined steel nozzle bricks, and the service life is longer.

Previous Page: