Application of Converter Magnesia Carbon Bricks

2025-08-14

Composition of BOF magnesia carbon bricks

BOF magnesia carbon brick is a magnesia carbon refractory product made of fused magnesia or high-purity sintered magnesia and high-purity graphite as the main raw materials, and is used for BOF lining. Its MgO content is not less than 95%, and its C content is not less than 94%. It is made of phenolic resin or asphalt as a binder through batching, mixing, forming, and heat treatment processes. It has the characteristics of high temperature resistance, strong slag resistance, and good thermal shock resistance. Antioxidants are usually added to improve the oxidation-prone defects.

Selection of magnesia carbon bricks for different parts

According to the damage characteristics of different parts of the converter, magnesia carbon bricks with corresponding properties should be selected: the furnace mouth and furnace cap parts should use products with strong thermal shock resistance and slag resistance; the two sides of the trunnion should use models with excellent oxidation resistance; the slag line part requires outstanding slag erosion resistance; the charging side focuses on high-temperature strength and thermal shock resistance; the furnace tank and furnace bottom should use high-grade magnesia carbon bricks with better comprehensive performance during combined blowing.

Each part of the BOF working lining faces different usage conditions, so the effectiveness of magnesia carbon bricks will also vary. The furnace mouth part of the furnace lining is continuously impacted by hot and cold molten steel, which requires the refractory material used here to be able to resist the erosion of high-temperature molten slag and high-temperature exhaust gas, and at the same time, it is easy to clean the hanging steel. The furnace cap area not only suffers from severe slag erosion, but also has to deal with rapid temperature changes, as well as the combined effects of high-temperature airflow and dust exhaust gas generated by carbon oxidation. Therefore, it is necessary to select magnesia carbon bricks with strong slag erosion resistance and spalling resistance. The charging side requires magnesia carbon bricks to not only have excellent slag erosion resistance, but also have excellent high-temperature strength and spalling resistance. High-strength versions with added metal antioxidants are usually selected. Studies have shown that magnesia carbon bricks containing metallic aluminum have lower high-temperature strength at low temperatures than samples with composite additions of metallic aluminum and metallic silicon, but at high temperatures, their strength is higher. As the key point where the furnace lining refractory material, high-temperature molten slag, and furnace gas converge, the slag line is the area with the most severe slag erosion. Therefore, magnesia carbon bricks with excellent slag erosion resistance must be selected, and the carbon content must be high.

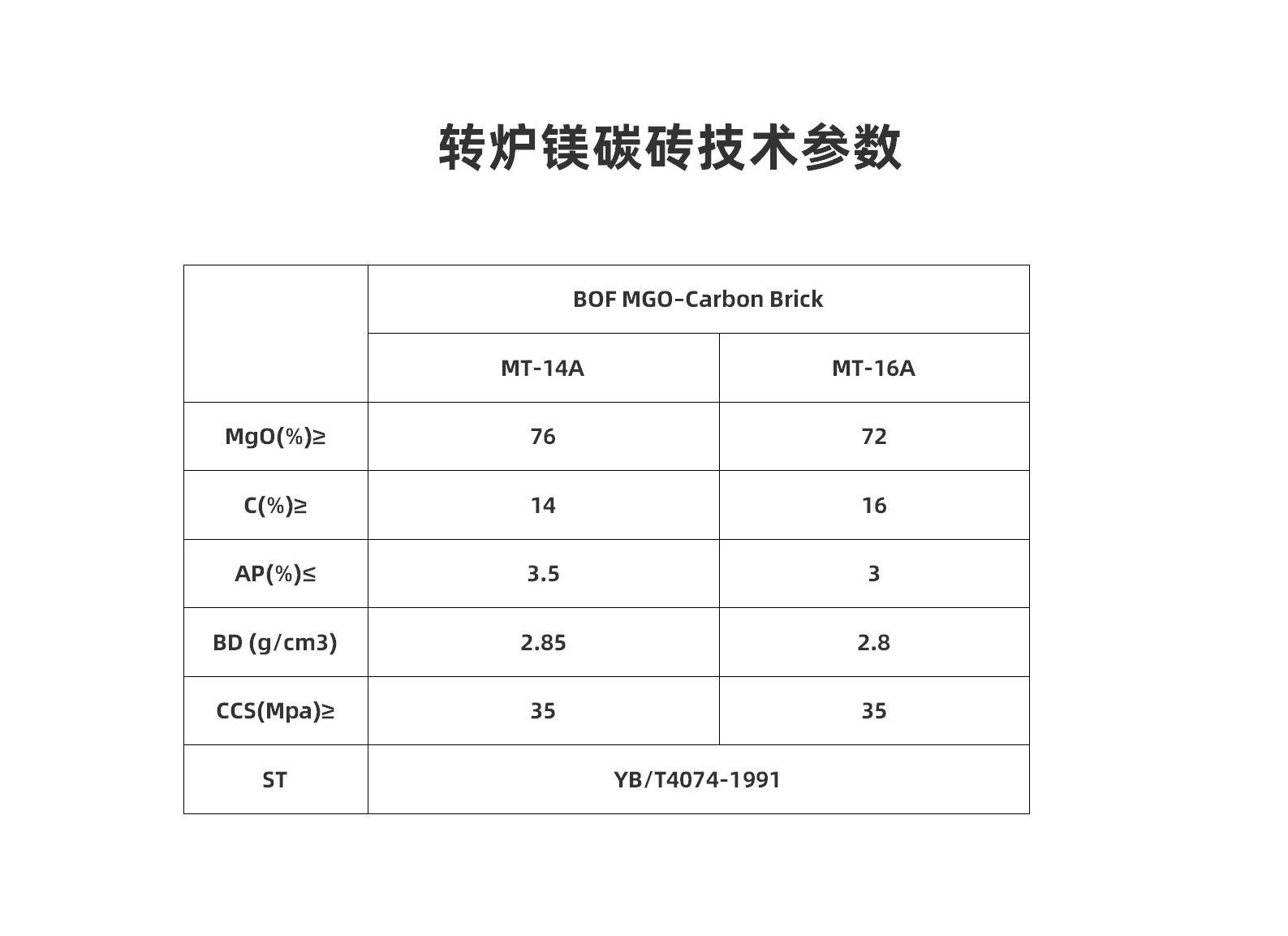

Technical parameters of magnesia carbon bricks produced by our company

Previous Page:

Next Page: