Slag Stopper Ball Technology

2025-08-18

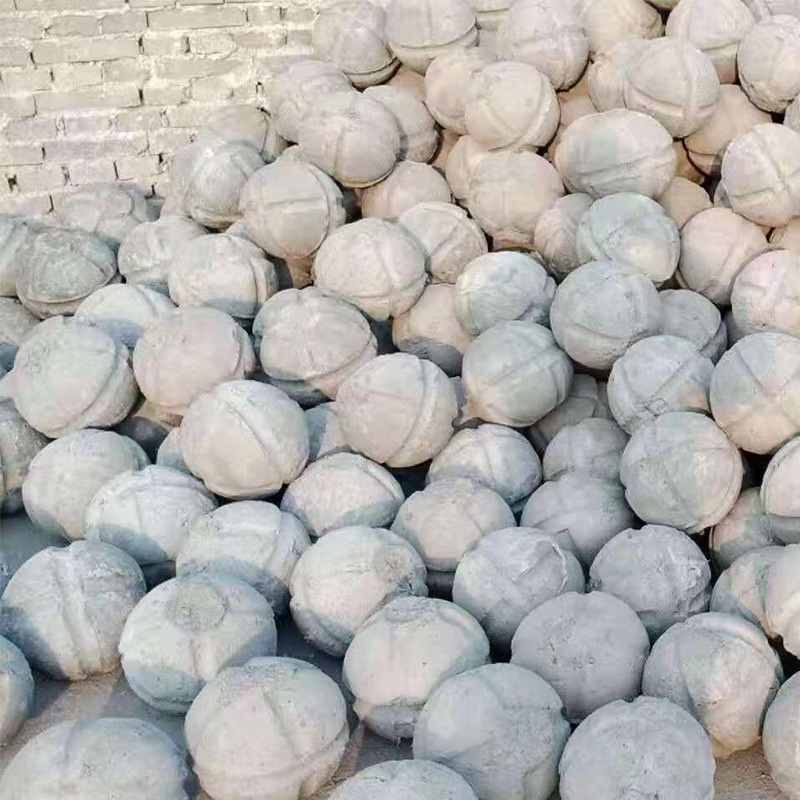

The slag retaining ball is a key device installed at the tapping hole in the converter steelmaking process, which realizes steel slag separation through physical interception. Its structure generally adopts a homogeneous design, and the surface is provided with annular grooves or spiral grooves to improve positioning accuracy. The slag retaining ball is accurately placed above the tapping hole by a robotic arm. Once the slag retaining ball falls into the tapping hole, it can effectively block the molten slag from entering the ladle.

Structure and working principle of slag retaining ball

The slag retaining ball adopts an ellipsoidal or standard spherical structure, and the surface is provided with vertical intersecting annular grooves or spiral grooves. The groove depth runs through the largest circumference of the sphere, which can maintain a vertical state in the swirling steel, and improve the positioning accuracy through hydrodynamic action. The spherical design includes a barite matrix and an iron particle mixing system, which realizes uniform density of the entire sphere through a vibration molding process.

The working principle relies on the flow characteristics of molten steel: after being put in, the sphere is adsorbed to the tapping hole above the molten steel buffer cavity, forming a filter barrier under the constraint of the tapered tapping hole structure (radius smaller than the sphere diameter). When the converter body is turned to the horizontal position, the molten steel flows out after being filtered by the slag retaining ball, and the residual molten slag is physically intercepted. This design can reduce the thickness of the slag layer in the ladle by more than 20%. Near the end of tapping, a slag retaining ball with a moderate density (usually 4.2~4.5g/cm³) is placed near the tapping hole in the furnace. As the liquid level of the molten steel decreases, the slag retaining ball will gradually sink and block the tapping hole, thereby effectively preventing molten slag from entering the ladle.

Structural design of slag retaining ball

The structural design of the slag retaining ball is crucial. Its center usually uses materials such as cast iron blocks, compacted pig iron filings, or small scrap steel billets as a skeleton, and the outside is wrapped with refractory mud. A reasonable slag retaining ball diameter should be slightly larger than the tapping hole diameter to ensure the slag retaining effect. In addition, for the problem that excessive slag viscosity may affect the slag retaining effect, the slag retaining ball can be put in advance to solve it.

Materials and manufacturing process of slag retaining ball

The slag retaining ball material system includes barite (1-95%), iron particles (0-79%), calcium aluminate cement (5-15%) and magnesia (0-5%). Data shows that a formula containing BaSO₄≥65% can reduce the consumption of silicon-aluminum-barium-calcium alloy (saving more than 3 kg per furnace). The outer refractory material mostly adopts high-aluminum castable or magnesia castable, and the density is optimized to 4.5g/cm³ to achieve suspension positioning between molten steel and top slag. The manufacturing process adopts the water mixing vibration molding method, and the melting corrosion resistance of the sphere is controlled by adjusting the raw material ratio. The utility model disclosed in 2024 shows that some products use a steel solid sphere as the base core (diameter 140mm), and the outer layer is covered with a 30mm refractory layer to form a composite structure.

Previous Page: